Seamless Technology~Superior Eco-Conscious Manufacturing

By ASI EFROS

As a designer by trade and a passionate proponent of sustainability and innovation, I’d love to point the attention of fellow creators to seamless technology as the most eco-conscious method of garment manufacturing that exists today.

Me Moi

Me Moi

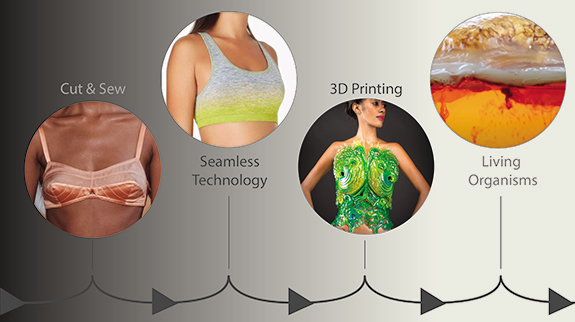

The traditional way of manufacturing garments, known as cut and sew, is the method by which the two-dimensional fabric is manipulated to make the garments fit our three-dimensional bodies. In order to accomplish this task, the textile is cut into multiple pieces and then put together by using one of the assembling methods like sewing or fusing. The waste in this method of creating garments is built into the technological process by default. No matter how precise the pattern marking and cutting techniques are, the portion of the material remains unused. Globally, this waste translates into thousands of tons of textiles that end up in landfills, proving the inefficiency of this manufacturing method.

The seamless technology, on the other hand, utilizes a more organic way of creating garments, which is very close to how it’s done by Mother Nature, i.e., efficiently and elegantly. In nature, objects grow as opposed to being assembled from separate components. If you watch how garments are produced by the seamless machines, you will observe the process of knitting, where row after row is added to the length of the garment. It appears as if the garment actually grows. It comes off the machine already preshaped to the three-dimensional form of the human body.

3D printing is another method of manufacturing that utilizes a nature-like way of growing objects, which, as I predict, will be used widely in the near future to produce all types of garments, from outerwear to intimate apparel. Currently, 3D printing is in the early stages of implementation on a larger commercial scale and is in the process of perfecting the methodology, printing equipment, and materials. I suspect that in the more distant future, the garments and lingerie will be grown on our bodies with the help of human-friendly bacteria and fungi.

The seamless knitting machines, both the circular, manufactured by Santoni, and the warp knitting, produced by Karl Mayer, are state-of-the-art equipment with the highest ranking in efficiency and use of electricity. They are also virtually no-waste, high-speed, and they assure full control of the knitting process, thus producing high-quality apparel. Another benefit of the seamless technology is that it requires almost no post-production finishing operations, which, in turn, translates into significant time, money, and energy savings. Guided by sophisticated software, both types of machines provide designers with endless creative possibilities in the implementation of various shapes, textures, colors, and patterns, thus allowing the creation of unique and innovative garments and collections.

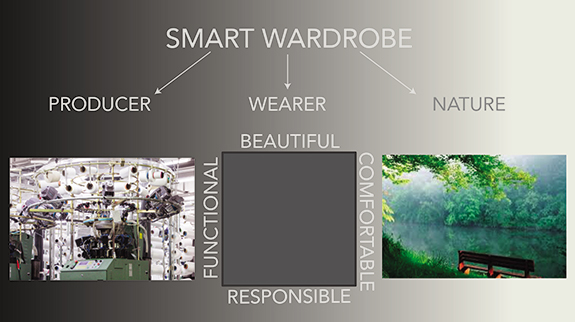

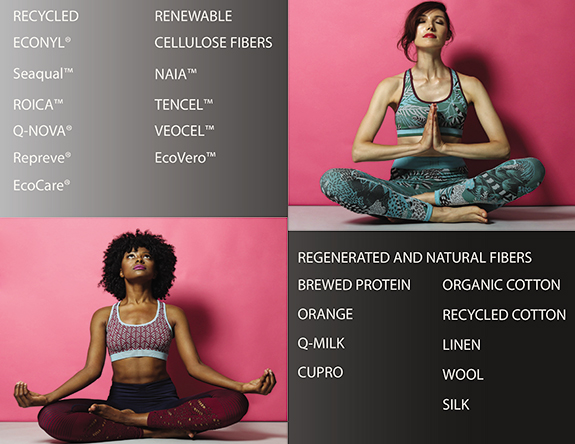

In the last decade, a tidal wave of sustainable yarns has entered the market. These fibers are produced using every known agricultural waste, plant, recycled plastic, as well as renewable resources like wood and bamboo. It is in combining sustainable yarns with the superb efficiency of the seamless technology that lays the foundation for manufacturing Smart Wardrobe; a generation of garments that positively impacts the producer, the wearer, and nature. The Smart Wardrobe is the concept that supports the holistic and balanced approach to manufacturing, which prioritizes quality over quantity and assures the survival of the human race on this planet.

Me Moi

Me Moi

The Smart Wardrobe consists of Smart Garments, which in turn encompass these four necessary requirements to be considered a viable apparel option. It is only if the garment, be it an outerwear or innerwear piece, excels in the function, comfort, beauty, and responsibility, both eco and ethical, it can be considered a Smart Garment.

The last ten years outline the renaissance in seamless manufacturing and its application in just about every apparel and non-apparel category, from car-seat covers to shoes, ready-to-wear, and jeans. The intimate apparel vanguards the march of innovation while seamlessly weaving this technology into activewear, loungewear, swim, daywear, and lingerie pieces.

MeMoi

MeMoi

While comfort, function, and responsibility components have been thoroughly explored in the design and development of seamless garments, beauty has been lagging. However, it is in the exploration of beauty and artistry, lie endless opportunities for brands highlighting their uniqueness, as well as earning the loyalty of their customers.

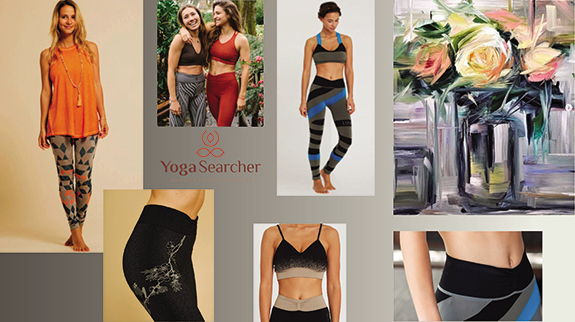

One of the brightest representations of the beauty infused in the seamless garments was the collection by Yoga Searcher, a french yoga-wear brand, which I discovered in Galleries Lafayette in Paris a few years ago. It occurred to me that the designer behind the brand Sandrine Schiele, treated the surface of the garments as if it was an artist’s canvas. She introduced patterned ombre effects, intarsia floral motifs, and color blocking to her seamless repertoire, thus transforming her garments into modern art masterpieces.

Another glorious manifestation of beauty and femininity is a patent-pending wire-free seamless bra developed by Mindd. Designed specifically for the large breasts in sizes D+, the bra embodies seven zones of differential compression to assure maximum support and lift. With its superb function and comfort, the beauty aspect of the bra is highlighted in the elegant lace pattern and feminine hues.

A great example of the artistry of the seamless craft is the range of the multi-purpose separates by MeMoi. In addition to the comfortable wide waistbands and curve-defining silhouettes, the garments include highly technical elements like the four-color jacquard and the two-color ombre effect that seamlessly transitions into openwork knit at the bottom of the legging. Last but not least, the complexity of the pattern design and the color palette elevates this vignette into the category of wearable art.

MeMoi

MeMoi

The full benefits of sophisticated technology, like seamless, can be best unlocked in the collaborative process between designers, who bring the ideas to the table, and the technical specialists, who understand the capabilities of the machines. It is there, in the incubator of creativity, inspiration, and know-how, the breakthroughs in innovations are conceived.

To learn more about seamless technology, visit www.karlmayer.com and www.santoni.com, or watch the Smart Voices webinar (Unlocking the potential of seamless technology to create a Smart wardrobe) organized by C.L.A.S.S.

Contact:

Giusy Bettoni: Founder/CEO, C.L.A.S.S. (Creativity Lifestyle And Sustainable Synergy)Website: www.classecohub.or

Email: Giusy@classecohub.org